|

Back to |

| The Front Page |

| News & Features |

|

Mallets and their makers: what’s new, what’s hot, and what actually works |

|

|

By Bob Alman with John Hobbs, Don Oakley, and Alan Pidcock layout by Reuben Edwards Posted April 17, 2004

|

|

If you have a mallet that weighs three pounds more or less and is a comfortable length, do its other characteristics matter much? Yes, they do, according to the experts. Whether you aspire to the world championship or merely winning third flight doubles with a good partner, you would probably want to make at least a small and reasonable effort to make sure you have the right mallet. The author has gone to the considerable trouble of finding out which are the most important factors for you to consider, not by doing a lot of lonely and laborious research, but by talking to three of the most highly regarded mallet manufacturers of the day. Although each has come into the business of mallet manufacture by different avenues, all are in substantial accord on the essential elements of the perfect mallet, they all produce fine products, and they all speak well of their competitors’ contributions to mallet design and manufacture. So they must be right. I pass along their wisdom to you, herewith, and invite your own observations in the conversation on our on-line Readers’ Forum on Mallet Design.

|

| This is a typical modern high-end mallet, with an 11-inch head, aluminum shaft, and roll bar near the head to absorb shock on the wrists. Photo by permission of the Oxford Website. |

Are you with me so far?

|

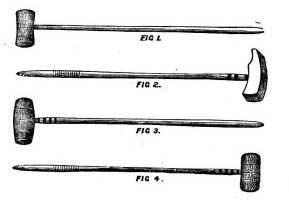

| From crude beginnings, mallets have evolved radically for 150 years as new materials and technologies have been discovered to meet the increasingly sophisticated standards of the sport. Photo by permission of the Oxford Website. |

My mallet is famously inadequate. People actually laugh at it, and of course I have taken a perverse pride in beating some players players who so ridiculed it. It bears the name Ultimate, made in Kentucky by the Wilhoites about two decades ago, and its most notable feature is the shaft, which is completely round, rubberized to absorb shock, and absolutely rigid, with a hollow core of fiberglass tubing. The overall weight is three pounds, and the balance point is 4 ½ inches from the top of the head. The best part is the head, which is 12 inches long, and made of some obviously indestructible plastic material. (The Wilhoites, who make what may be the best overall croquet ball in the world among the four WCF-approved brands, especially pride themselves on the durability of their products.)

All well and good, except for the shaft. The shaft, in the context of today’s conversation about mallet characteristics, is a scandal. Although there is one New Zealand mallet-maker who sells round-shafted mallets, he is one of very few who will say anything good about that shape.

Hobbs and the adjustable grip

Among the three mallet-makers I interviewed for this article, John Hobbs makes the most telling argument against the round shaft, citing a principal of coaching: You should automate everything possible in the mechanics of the stroke, and that includes getting a shaft that fits naturally into your grip with the head of the mallet pointed straight ahead. With a round shaft, you have to point the mallet head intentionally each time you prepare to make shot, rather than have the mallet fit naturally into your hand and pointed straight ahead.

If you place your hands at the level of your navel in the positions you would use to hold your mallet, looking straight down, you will see that god did not design mallet and grip to fit together ideally at neat 90-degree angles, with perhaps the one exception of the seldom-used Solomon grip – which Hobbs says works best if the narrow axis of the shaft points straight ahead, incidentally. The standard grip seems to work best at an angle of fifteen degrees or so, while top players make a more radical adjustment for the Irish grip, up to 45 degrees.

A little knowledge is a dangerous thing, and this knowledge has shaken my already mushy self-confidence. Now that it has been pointed out, I see that every shot with my round-shafted mallet must begin by casting and adjusting my grip to get the mallet pointed straight ahead – instead of having it fit naturally into my grip at the correct angle. So, if for no other reason, I will have to get rid of my oh-so-distinctive mallet, so I can get one that fits naturally into my Irish grip.

Each of the three mallet-makers started out with a single “big idea” behind his unique product. Hobbs’ “big idea” was to set the shaft at an angle to suit the standard grip – an angle that turned out to be about 15 degrees away from center for the standard grip. This is the way he explained it to me:

“For players with the standard grip, .I provide them with an octagonal mallet shaft, which has a long axis and a short axis, and I recommend that the short axis be the one that’s front to rear, contrary to what people usually have – by reason of the fact that if you wrap your fingers around the shaft, you see a gap which is longer from left to right that it is from front to rear. So the handle fits beautifully in there with the long side of the octagon roughly parallel to your body.

“But what you find is that if you have it at exactly 90 degrees to the front and rear of the head, the head will probably be pointing about 15 degrees away from a true line. And this is purely a function of body geometry. Therefore you find that most players who make this investigation find out that their handles should be set about 15 degrees from a perfect right angle.”

Clear enough. But what about the Irish grip? As it turns out, the Irish grip requires an even more radical adjustment of the angle of the shaft to the head. He discovered this when Stephen Mulliner, one of Britain’s best players, bought the Hobbs mallet precisely because he wanted to be able to adjust it easily to his grip. “Mulliner had been carving away at his old mallet,” Hobbs said, “such that it gave him that 45 degrees, so when he saw that he could turn the handles on my mallet, he said, ‘That’s exactly what I want to do.’ He was the first to see the benefit of my mallets for adjusting them to the Irish grip.” Among the other eminent players who have looked to Hobbs for mallets to suit their grip styles are world #2 Reg Bamford and America's youngest champion, Jacques Fournier.

According to Hobbs, once you fit the shaft comfortably into your grip, finding the correct angle is a simple matter: “All you’ve got to do is make sure that when you take your stance your body is lined up correctly, and if it is, you just swing straight ahead, and you should hit the ball. If you don’t hit the ball, then what I suggest to people when they buy a new mallet is that they take shots at an object like the peg, and if it misses consistently to one side, they have only to put the head between the feet, twist the head around, and make the correction.”

Hobbs makes about 100 mallets a year in his garage under the name of Bespoke Mallets and ships them with the end screw lightly tightened, so players can make repeated fine adjustments until they are satisfied with the angle.

Alan Pidcock:

The physics of gravity, impact and momentum

All the best mallet makers have at least a basic understanding of the laws of physics and apply that knowledge to making their mallets. But Alan Pidcock, a chemist by training, has put physics at the center of his philosophy of mallet-making. He tests balls submitted for official certification by the World Croquet Federation and reports minutely on all their characteristics, from milling to rebound, uniformity and temperature tolerances. When he thinks of mallets, he first considers the "moment of inertia" (MOI) and its effect on the interaction of mallet and ball.

I have difficulty with these concepts from physics, so I asked for an extended explanation: "In straight-line motion," Pidcock explained, "a heavier mass is harder to get into motion (ie. to accelerate from rest) than a lighter mass. In rotational motion (such as twisting the head of a mallet), the greater the mass, the more difficult it is to twist."

Fair enough. To illustrate even more precisely, he uses the example of a flywheel: "A flywheel has a heavy rim and minimal mass inside: most of the mass is at maximum distance, so the moment of inertia (MOI) is maximized and the flywheel is harder to get into motion than a uniform disk, but it's also more difficult (requires more torque) to change its angular velocity. Hence, the flywheel smoothes out variations in torque."

So far, so good. As applied to mallets, "A ball struck by the center of the face of the mallet causes no left/right twisting force, so the MOI is irrelevant. But a ball struck towards the edge of the face imparts a twist to the head which will begin to rotate whilst still in contact with the ball. If the MOI is high, the rotation of the head will be slower and the extent of twist in the duration of contact will be smaller. This means that the proportion of properly directed shots that hit the target increases with the MOI, because more off-center strikes will hit, also.

"The design aim is to move as much of the mass of the hitting implement as far away from the pivot axis as possible. In croquet, the rules say both faces of the mallet must play identically, so the best that can be done is to have equal weights as close to the striking faces as possible.

"So 'peripheral weighting’ in croquet means as far from the pivot as possible, and for mallets, this means 'ends' - not 'the rim of the faces' as in golf irons. Some mallet designs have put the weight at the sides behind thick composite faces - but the center of mass of the weights is then at a significantly shorter distance from the pivot point."

Could a fraction of an inch really make that much difference? It can, says Pidcock, quoting more physics: "Maximizing the distance is important because the MOI depends on the square of distance, so a 10% increase in distance increases the MOI by 21%."

Clearly, Pidcock has done everything he practically can to maximize the "moment of inertia" in his mallet design and thus make it a better one-ball hitting machine.

|

| The round head of Alan Pidcock’s “2001” mallet is a sparkling object of beauty that maximizes the advantages of peripheral weighting. Photo by Alan Pidcock. |

Although Pidcock’s strikingly beautiful mallets have cylindrical heads, he has never claimed that roundness per se is an advantage, only that his design gives much more peripheral weighing than most other designs. Here’s the kicker: other mallets that use the same physics put the brass weights behind a composite face that is up to ¼ inch thick, but not Pidcock’s: “Many mallets have lead behind two 1/4" layers of composite on the striking faces,” he explains. “Since the composite is of much lower specific gravity and lower density than the lead, the effect is to reduce the MOI by pushing the lead closer to the shaft. I now have no facing material on the brass, so the brass center of mass is absolutely as far from the shaft as it can get.”

He’s gone about as far as he can go

Even though he has sold more than 2,000 mallets, Pidcock’s interest in mallet making does not extend to competing at the most basic end of the market. His mallets, he says, of whatever materials, are designed to be aesthetically attractive, with sustainably managed hardwood heads, inlaid sight lines, themed with black coloring on the faces, shafts, handles and grips; with collars and end faces, and even a gold plated collar on the 2001 design.

”I want to use fine materials,” he says, “and to take advantage of new materials to improve technical quality, and to steer clear of others' innovations - like John Hobbs' rotatable shaft. We pioneered the use of carbon fiber in shafts Our mallets should be capable of repair and renovation almost indefinitely.”

Just to be clear, Pidcock’s company, Manor House Croquet, has not abandoned wood – not at all. “I also do a hollow square section wooden head with solid brass end plates. Hollowing lightens the body, whilst permitting use of a hard (heavy) wood, which is important for durability. Our stock of head timber was specially imported from Paraguay for me and it's in one-meter lengths, so I can make any wooden head shorter than one meter!”

What does the future hold in the way of technical advances? Pidcock doesn’t have a lot to say about that: “The 2001 is now close to a limit in terms of cost and materials: although I could make some technical improvements, they would be relatively small and quite expensive.

Obviously, when you ask what the “best” mallet in the world is, you have to add so many qualifiers for “best” that it’s a dubious question. Pidcock will say, however, that for most purposes, his 'best' mallet is the round-headed 2001. “But if your mallet has to be square, the brass ended wooden head is available. The 'best' also depends on whether you’re playing Golf Croquet, American Rules, or International, but the 2001 optimizes the benefit of peripheral weighting in either case for the single-ball hit-in.”

Don Oakley’s mallet for the masses

|

| Don Oakley of Canada produces the “Chevrolet” of croquet mallets for the masses. Photo by Don Oakley. |

Oakley’s father was a physics teacher, and his grandfather was a tool and die maker, so he claims that a knowledge of mechanics is in his genes. “But woodworking allowed me to make something that people can appreciate, rather than fixing broken machines.”

Oakley found a vague sense of satisfaction in making his first mallets, which were admittedly crude – “although their owners were quite happy and played with them for years”, he says. Eventually, in the mid 90’s he met Bill Langstroth, the founding president of Croquet Canada, who helped him with his first strokes of croquet as well as with the development of his more sophisticated mallets. The result was the mallet that still leads Oakley’s line: the Brighton mallet.

The Brighton mallet is still popular almost 10 years after it’s introduction. He believes that’s because it’s extremely durable – it can’t be broken, now that thicker walled aluminum shafts have been added to the hardy plastic head – and it’s not expensive.

Oakley explains, “It was originally designed to meet the budget of the novice player who wasn't prepared to invest a great deal of money into a sport that they may not stay with. Having said that, Bob Kroeger (and many others) swears by this mallet as the best stop shot machine he knows. It is his mallet of choice. Bob told me early on that what croquet needed was a "Chevrolet" - a mallet reasonably priced that performs well; a mallet for the masses. That is the Brighton mallet.”

The Brighton's major development breakthrough was not in the unique shape of the head but a better method of fixing the shaft to the head. The plastic used for this head didn't allow for the traditional wedge tenon joint. This is inherently a flawed design. End grain, exposed on the bottom of the mallet, absorbs moisture as soon as the finish is scuffed. The moisture then works to loosen the shaft in the head.

The materials Oakley contemplated using for the Brighton forced him to rethink this critical aspect of mallet design. His machining background reminded him of the gripping strength of the tapered cone. “Once I settled on the concept,” Oakley recalls, “the rest fell into place. It wasn't long before I realized that with this fitting, changing heads and shafts was much easier and one never had to tolerate a loose head. The single bolt fitting meant that anyone who could turn a bolt could change a head or shaft or dismantle it for airline travel.”

To Hobbs’ surprise, Oakley hasn’t made much, in his advertising, of the advantages of his adjustable grip by virtue of his TaperLock. Perhaps that’s because the idea of the adjustable grip has not broadly penetrated the consciousness, yet, of ordinary club players.

Oakley’s next revelation followed in the spirit of Henry Ford, the early 20th Century American guru of mass production. “I realized that entire mallets need not be developed at once,” Oakley says. “Each new head or shaft would be made with the same, TaperLock fitting. Each new head then fits any existing shaft. We now have a stable of mallets thanks to this 'interchangeability' factor. When a player comes to us for a mallet, it can be customized to suit their specific needs. Each combination of head and shaft offers its own unique blend of weight, torsional strength, balance point, aesthetic qualities and price. Product development is also easier this way. I can concentrate my efforts on just a head or just a shaft, knowing that I have the mate to complete the picture.

Oakley found his “mass market,” insofar as such a thing exists in the tiny sport of croquet. “The majority of those using our mallets are mid-range handicap players,” he admits. “This is not to say that lower handicap players aren't using them - there are. Some ultra low handicap players have been leaning toward different new designs.”

Oakley went to the MacRobertson Shield in West Palm Beach to talk to some of the best players in the world about the mallets they’ve chosen to compete with. “The results were interesting to say the least,” Oakley says in a puzzled tone. “The range of mallets ran the gamut from home-made all wood mallets with no reinforced striking faces to all-graphite units with brass ends. There were shafts made of wood, aluminum, fibreglass and graphite. Heads too, had the same variety of materials. Interestingly, no one type of mallet offered its owner a distinct advantage over the field, judging from the results.”

Does that mean that mallet design really doesn’t matter much, within a broad range of standard factors? “I hope not,” Oakley replies. “As different materials and designs are explored, we learn more about the physics of the game. We also learn about human nature. Much of what makes a player better is a comfort level with their mallet.

“The subject of weighting offers two major opinions. . First is the traditionalist who believes that the best performing mallets have a static balance point about 20% up the mallet (from the ground). I believe there is something to this. When a mallet hits a ball, it is initially moving forward. The ball wants to stop the head, while the top of the shaft doesn't share the same desire. Somewhere along the length of the shaft, those two forces converge. If that point is well positioned, the mallet "feels right". It’s a touchy-feely thing that I have yet to quantify. Second in the weighting department is lowering the center of gravity (COG). This allows a lighter mallet to perform like its heavier (high COG) cousin. Counteracting the twisting of the mallet on impact with the ball requires as much weight as possible to be placed as far from the axis of rotation as possible. The axis in this case is the centerline of the shaft. Given that mallets are longer than they are wide, the weight is most effectively placed in the striking faces or directly behind them. I have a couple of prototypes that are being developed to address this issue. I feel it is an important one.”

Clearly, the maker of “mallets for the masses”, having quite accidentally adopted Hobbs’ adjustable grip philosophy, is now also on the heels of Pidcock’s innovations. But for the immediate present, Oakley is most interested in another application of “interchangeable parts” - adjustable weighting.

The customer does the customizing

“As my mallets evolve,” Oakley declares, “I am putting more choices into the hands of the players. It's not uncommon for a player to change mallets as the court speeds up in the day. If they don't change their mallet, they definitely change their playing style. One feature I have recently introduced is the concept of adjustable weighting. Current understanding is that a lower center of gravity allows for an overall lighter mallet to impart the same energy transfer on a ball as a heavier mallet with a higher center of gravity. In keeping with this concept, I have recently introduced a mallet with adjustable weights. The weights reside in the sole of the mallet and allow for a graduated variation of up to 7 ounces from lightest to heaviest.

“With this mallet, a player can easily deal with changing lawn speeds – and this is a real issue at the ordinary club levels, where the grass might be cut no more than twice a week. It also allows the player to experiment with their playing style by having one mallet whose one variable is weight. Next to mallet height, weight is the most common characteristic a player may want to alter.

If you’re not ready for adjustable weighting, what is the one right weight to choose? “Until I have some hard data to apply to my mallet designs,” Oakley says, “I will maintain that three pounds gives you the most versatile mallet. It is heavy enough for most players to do a double ball cross-court shot while at the other end of the spectrum, it makes a great stop shot. Add more than a few ounces to this, and stop shots will suffer but long shots improve. Each player's individual style will make the final determination here.

“I choose not to compromise my designs by material limitations. I am perpetually looking at everything around me to understand how it works and how it is made. Raw materials offer a jumping off point for my design process. Many times I will want to make something and for the most part, anything can be made once. The challenge comes when you need to make multiples at a reasonable price. My shop has a number of "one of a kinds" because they haven't been able to be made economically.

“One of the wonderful aspects of what I do in research is how suppliers in other industries react when I ask them for information about their products as they apply to building a better croquet mallet. ‘A croquet mallet?’ they say. ‘You want this to make a mallet? I remember croquet in my grandmother's backyard . . .’ Now that I have their attention, it makes my research easier because they’re curious and have a warm, nostalgic feeling about croquet."

Don Oakley is the youngest manufacturer we have interviewed, and unless someone stops him, he will produce and sell many thousands of mallets for the masses as his designs continue to evolve in response to the choices of his customers and his continued research and experimentation. He is already America’s biggest mallet merchant, and it’s quite possible that he will become in due time the sport’s biggest on-line merchant as well, through his excellent website.

The questions that remain

There is a great deal of consensus among our mallet makers about what constitutes the best mallet, but it’s also clear that ultimately the choices are just about as individualistic as the players themselves: How much do they want to spend? What is most important to them – the single-ball hit in that you need in the “Association Laws” game, or the consistently low-ratioed stop-shot you should best have at running breaks, especially in the American Rules game? How does your chosen grip affect the facts of shaft height and mallet weight? Are you tall enough to handle the 11- or 12-inch mallet head that maximizes the peripheral weighting benefit, or should you settle for a shorter head so you won’t hit the ground so often? Must your mallet be square, after all, or are you irresistibly attracted to the sleek and sensuous sheen of the traditionally rounded Pidcock? Is it really worth it to get a mallet whose shaft can be easily adjusted in minute degrees to fit your grip? How much “whip” do you want in the mallet to avoid wrist injuries and at the same time minimize vibration? How heavy should the mallet be, to enable you to get across the lawn without pushing? How light does it need to be to give you the stop shot you need? And how can you possibly balance all these factors to come to a decision?

My advice is this: If you have a mallet you can love as it is, learn how to use its characteristics to maximum advantage. If not, your search for the ideal mallet has already begun with these three mallet makers, whose lovingly crafted products, taken all together, embrace every one of the issues you will need to address. Good playing to you, and good luck!

JOIN OUR ON-LINE FORUM: Add your voice to this article by joining the discussion in our online Forum on Mallet Design.

CONTACT THE MALLET-MAKERS through the Directory of Croquet Manufacturers, Distributors, and Service Providers on the USCA Website.

Alan Pidcock,

Manor House Croquet

1 Barn Croft,

Penwortham, Preston, PR1 0SX.

Tel: 01772-743859.

Email: pidcock@manorh.u-net.com

Don Oakley,

Oakley Woods

P.O. Box 3045, Brighton,

Ontario, Canada K0K 1HO

(613) 475-3541

E-Mail: inquiries@oakleywoods.com

John Hobbs Mallets,

The Lewins, Mayfield Road,

Rotherfield, E. Sussex

TN6 3LS, England, UK tel 01892 852072

E-Mail: HobbsMall@aol.com